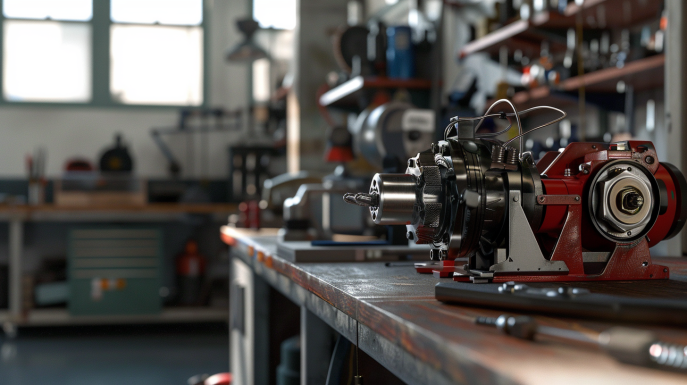

Power Torque Tools Air Compressor – PAC06501

- Power Supply: DC12 Volt Rated Current: 14A Cylinder Diameter: 30mm Max Pressure: 140psi Max Duty Cycle: 40 Minutes Outflow: 1500 Cube Inch/Min Air Hose: 3 Foot Cord: 10 Foot;

- A Power Torque 12-volt portable air compressor is designed to quickly air up a flat or low tire and can be stored easily in your vehicle with the included carry bag.

Harnessing Compressed Air for Maximum Efficiency

In the world of tools and machinery, few devices pack as much punch as the power torque air compressor. Whether you’re a DIY enthusiast, a professional mechanic, or an industrial operator, understanding the ins and outs of these powerful machines can significantly boost your productivity and efficiency. Let’s dive into the fascinating world of power torque air compressors and explore how they can revolutionize your work.

What’s the Buzz About Power Torque Air Compressors?

At its core, a power torque air compressor is a mechanical marvel designed to convert power into potential energy stored in pressurized air. These machines are the unsung heroes of many industries, silently powering a wide array of pneumatic tools and processes. But what sets them apart from their conventional counterparts?

Power torque air compressors are engineered to deliver a higher torque output, which translates to more power and efficiency in your air-powered tools. This means you can tackle tougher jobs with ease, whether you’re inflating tires, operating nail guns, or running heavy-duty industrial equipment.

The Inner Workings: How Does the Magic Happen?

To truly appreciate these machines, it’s essential to understand their operation. Power torque air compressors typically use a piston mechanism to compress air, storing it in a tank for later use. When you activate an air tool, the compressed air is released, providing the necessary force to power your equipment.

What sets power torque models apart is their ability to maintain consistent pressure and deliver a higher volume of air, ensuring your tools operate at peak performance even under demanding conditions. It’s like having a tireless assistant that never runs out of breath!

The Perks of Powering Up with Torque

Investing in a power torque air compressor comes with a host of benefits that can transform your workflow:

- Enhanced Performance: Say goodbye to underpowered tools and hello to efficient, high-powered operation.

- Versatility: From light-duty tasks to heavy industrial applications, these compressors can handle it all.

- Energy Efficiency: Many models are designed to optimize energy consumption, saving you money in the long run.

- Durability: Built to withstand tough conditions, power torque compressors often boast longer lifespans than standard models.

- Quiet Operation: Despite their power, many of these compressors are engineered for quieter operation, making them ideal for noise-sensitive environments.

Navigating the Sea of Options

When it comes to power torque air compressors, one size certainly doesn’t fit all. The market offers a diverse range of options to suit various needs:

- Portable Compressors: Perfect for contractors and DIY enthusiasts who need to move their equipment from job to job.

- Stationary Units: Ideal for workshops and industrial settings where a constant supply of compressed air is required.

- Oil-Free Models: Great for environments where air purity is crucial, such as in food processing or pharmaceutical industries.

- Belt-Driven Compressors: Known for their quiet operation and efficiency in continuous-use scenarios.

- Direct-Drive Units: Compact and requiring less maintenance, these are popular in smaller workshops and garages.

Finding Your Perfect Match: Choosing the Right Compressor

Selecting the ideal power torque air compressor involves more than just picking the biggest or most expensive model. Consider these factors to make an informed decision:

- Air Pressure Requirements: Determine the PSI (pounds per square inch) needed for your tools.

- Air Flow Capacity: Look at the CFM (cubic feet per minute) rating to ensure sufficient air supply.

- Tank Size: Larger tanks mean less frequent cycling, which can extend the compressor’s life.

- Portability Needs: Will you need to move the compressor, or will it stay in one place?

- Power Source: Consider whether you need an electric or gas-powered model.

- Noise Level: If you’re working in residential areas or noise-sensitive environments, opt for quieter models.

- Duty Cycle: For continuous operation, look for compressors with 100% duty cycles.

Brand Power: Who Makes the Cut?

While there are numerous manufacturers in the market, some brands have established themselves as leaders in the power torque air compressor space:

- DeWalt: Known for their robust and reliable compressors suitable for both professionals and DIY enthusiasts.

- Ingersoll Rand: A go-to choice for industrial-grade compressors with outstanding performance.

- California Air Tools: Renowned for their ultra-quiet, oil-free models.

- Makita: Offers a range of compact yet powerful compressors popular among contractors.

- Atlas Copco: A top pick for heavy-duty industrial applications.

Remember, the best brand for you depends on your specific needs and budget. Don’t hesitate to read user reviews and compare specifications before making your decision.

Power Torque in the Garage: A Mechanic’s Best Friend

For automotive enthusiasts and professional mechanics, a power torque air compressor is nothing short of essential. These machines can power a wide range of pneumatic tools, including impact wrenches, spray guns, and tire inflators. The high torque output ensures you can easily remove stubborn bolts or quickly inflate large truck tires.

When choosing a compressor for automotive use, pay special attention to the CFM rating. Most air tools used in automotive work require a higher air volume, so opt for a compressor that can keep up with your demands.

Electric vs. Power Torque: Understanding the Difference

While both electric and power torque air compressors serve similar purposes, there are key differences to consider:

- Power Output: Power torque compressors generally offer higher power output, making them suitable for more demanding applications.

- Portability: Electric compressors are often more portable, while power torque models may be larger but offer greater capacity.

- Energy Source: Electric compressors plug into an outlet, while power torque models may use gas or diesel engines, offering more flexibility in remote locations.

- Maintenance: Power torque compressors may require more maintenance due to their complex engines, but they often have longer lifespans.

Keeping Your Compressor in Top Shape

To ensure your power torque air compressor serves you well for years to come, proper maintenance is key:

- Regular Oil Changes: For oil-lubricated models, change the oil as recommended by the manufacturer.

- Air Filter Cleaning: Clean or replace air filters regularly to maintain efficiency.

- Drain the Tank: Remove moisture from the tank after each use to prevent rust and contamination.

- Check for Leaks: Regularly inspect hoses and connections for air leaks.

- Tighten Bolts: Vibration can loosen bolts over time, so check and tighten them periodically.

- Professional Servicing: Schedule annual check-ups with a professional technician for optimal performance.

Safety First: Using Your Compressor Responsibly

While power torque air compressors are invaluable tools, they require respect and caution:

- Always wear safety glasses and ear protection when operating the compressor.

- Never exceed the recommended pressure for your tools or the compressor itself.

- Ensure proper ventilation, especially for gas-powered models.

- Keep the compressor clean and free from oil and grease to prevent fire hazards.

- Never use compressed air to clean yourself or others – it can cause serious injuries.

- Disconnect the power source before performing any maintenance.

Storage Solutions: Keeping Your Compressor Ready for Action

Proper storage is crucial for maintaining your compressor’s performance and longevity:

- Store in a clean, dry area to prevent rust and corrosion.

- Use a cover to protect from dust and debris when not in use.

- For long-term storage, drain all air and moisture from the tank.

- If storing outdoors, ensure the compressor is protected from the elements.

- For portable models, secure them to prevent tipping or rolling.

Troubleshooting Tips: When Things Don’t Go as Planned

Even the best compressors can encounter issues. Here are some common problems and quick fixes:

- Compressor Won’t Start: Check the power source, fuses, and circuit breakers.

- Low Pressure: Look for air leaks or a clogged air filter.

- Excessive Noise: This could indicate loose parts or low oil levels.

- Overheating: Ensure proper ventilation and check for any blockages.

- Moisture in the Air Lines: Drain the tank more frequently and consider installing a water separator.

Making the Purchase: Where to Find Your Perfect Compressor

Power torque air compressors are available from various sources:

- Home Improvement Stores: Retailers like Home Depot and Lowe’s offer a range of options for DIY enthusiasts.

- Industrial Suppliers: For professional-grade equipment, check out suppliers like Grainger or MSC Industrial Supply.

- Online Marketplaces: Amazon and eBay provide a wide selection and often competitive prices.

- Direct from Manufacturers: Many brands sell directly through their websites, often with excellent customer support.

Budgeting for Power: What to Expect Price-wise

The cost of a power torque air compressor can vary widely based on size, power, and features:

- Small, portable models: $100 – $500

- Mid-range compressors for workshop use: $500 – $1,500

- Large, industrial-grade units: $1,500 – $5,000+

Remember, investing in a quality compressor can save money in the long run through improved efficiency and durability.

Spec Check: What Numbers Matter?

When comparing compressors, pay attention to these key specifications:

- Horsepower (HP): Indicates the motor’s power output.

- CFM (Cubic Feet per Minute): Measures air flow capacity.

- PSI (Pounds per Square Inch): Denotes the maximum air pressure.

- Tank Size: Measured in gallons, affects how long the compressor can run before needing to refill.

- Duty Cycle: The percentage of time the compressor can run continuously.

- Noise Level: Measured in decibels (dB), important for noise-sensitive environments.

Learning the Ropes: Resources for Mastering Your Compressor

While written guides are helpful, visual aids can be invaluable for learning to use your compressor effectively. Check out YouTube for tutorials on setup, maintenance, and troubleshooting. Many manufacturers also offer instructional videos on their websites.

Industries Powered by Torque

Power torque air compressors find applications across numerous industries:

- Construction: Powering nail guns, jackhammers, and spray painters.

- Manufacturing: Operating assembly line tools and pneumatic controls.

- Automotive: Inflating tires, powering impact wrenches, and spray painting.

- Agriculture: Operating pneumatic equipment and spraying systems.

- Mining: Powering drills, pumps, and ventilation systems.

- Healthcare: Running medical equipment and laboratory instruments.

Alternatives to Consider

While power torque air compressors are versatile, they’re not always the best choice for every situation. Consider these alternatives for specific needs:

- Electric Air Compressors: For lighter duty or indoor use where emissions are a concern.

- Hydraulic Systems: When extremely high force is required.

- Battery-Powered Tools: For ultimate portability in low-power applications.

- Manual Tools: Sometimes, good old-fashioned elbow grease is all you need!

Rent or Buy: Weighing Your Options

If you’re not ready to commit to a purchase, renting a power torque air compressor can be a great option:

Pros of Renting:

- Try before you buy

- Access to high-end models for short-term projects

- No long-term maintenance responsibility

Cons of Renting:

- Higher cost over time for frequent use

- Limited availability of specific models

- Potential for hidden fees or damage charges

Many equipment rental companies and some home improvement stores offer compressor rentals. This can be an excellent way to test different models and determine your exact needs before making a purchase.

In conclusion, power torque air compressors are powerful allies in a wide range of industries and applications. By understanding their capabilities, maintenance needs, and how to choose the right model, you can harness the power of compressed air to elevate your work to new heights. Whether you’re inflating tires, powering tools, or running industrial equipment, the right power torque air compressor can be a game-changer in your operations. So, take the time to assess your needs, do your research, and invest in a compressor that will serve you well for years to come. With the right knowledge and equipment, you’ll be well on your way to mastering the art of compressed air power!