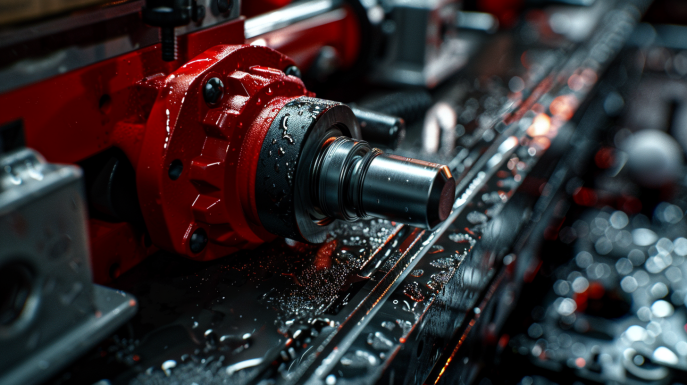

Power Torque Tools 2 Ton Floor Jack – PT34136

- A Power Torque 2-ton floor jack is designed for easy, safe use by both professional and DIY mechanics. This Power Torque floor jack offers a lifting range of 5 inches to 13 inches, and can easily be placed in the correct position under the vehicle thanks to the rear caster wheels. Each floor jack includes a removable 16-1/2 inch long handle for optimal leverage and quick, secure lifting. Power Torque floor jacks are made from high-quality steel for durability and feature a blue powder coat finish to help prevent rust and corrosion and extend tool life.

Elevate Your Lifting Game with Precision and Ease

In the world of heavy lifting and precision mechanics, few tools are as indispensable as the power torque jack. Whether you’re a seasoned professional or a DIY enthusiast, understanding the ins and outs of this powerful device can revolutionize your approach to lifting and positioning heavy loads. Let’s dive into the fascinating world of power torque jacks and discover why they’re becoming the go-to choice for those who demand efficiency and accuracy in their work.

What Exactly is a Power Torque Jack?

At its core, a power torque jack is a sophisticated lifting device that combines the brute force of hydraulic or electric power with the precision of torque control. Unlike traditional jacks that simply lift, power torque jacks allow you to both lift and apply precise rotational force to an object. This dual functionality makes them invaluable in a wide range of applications, from automotive repairs to industrial machinery maintenance.

Imagine being able to lift a multi-ton piece of equipment and then rotate it with micrometer accuracy – that’s the power of a torque jack at your fingertips. It’s like having a superhuman assistant that never tires and always hits the mark.

The Magic Behind the Machine: How Power Torque Jacks Work

The operation of a power torque jack is a beautiful dance of engineering principles. At its heart lies a powerful motor – either hydraulic or electric – that generates the lifting force. This force is then channeled through a series of gears and mechanisms that allow for both vertical lift and rotational movement.

The secret sauce? Precise control systems that enable the user to modulate both the lifting height and the applied torque. It’s this level of control that sets power torque jacks apart from their simpler cousins. You’re not just lifting; you’re orchestrating a symphony of force and movement.

Why Power Torque Jacks are Changing the Game

The benefits of using a power torque jack are numerous and game-changing:

- Unparalleled Precision: Need to lift a delicate piece of machinery and rotate it exactly 37.5 degrees? A power torque jack has got you covered.

- Enhanced Safety: By reducing the need for manual handling, these jacks significantly decrease the risk of workplace injuries.

- Time and Labor Savings: What used to take a team of workers can now often be accomplished by a single operator with a power torque jack.

- Versatility: From automotive work to industrial applications, these jacks are the Swiss Army knives of the lifting world.

- Increased Productivity: With faster setup times and more efficient operation, you’ll be tackling more jobs in less time.

Navigating the Sea of Options: Types of Power Torque Jacks

When it comes to power torque jacks, one size definitely doesn’t fit all. The market offers a variety of options to suit different needs:

- Hydraulic Power Torque Jacks: These beasts excel in high-load situations, offering unmatched lifting capacity.

- Electric Power Torque Jacks: Perfect for environments where hydraulic fluid is a no-go, these offer clean, quiet operation.

- Portable Power Torque Jacks: For those on-the-go jobs, these compact models pack a punch without sacrificing mobility.

- Heavy-Duty Industrial Power Torque Jacks: When you need to move mountains (almost literally), these are your go-to.

- Precision Power Torque Jacks: For applications where accuracy is paramount, these specialized jacks offer unparalleled control.

Finding Your Perfect Match: Choosing the Right Power Torque Jack

Selecting the ideal power torque jack is like finding a soulmate for your workshop. Here’s what to consider:

- Load Capacity: Always choose a jack rated well above your heaviest expected load.

- Power Source: Consider your work environment. Is hydraulic power available, or do you need the flexibility of electric?

- Precision Requirements: How accurate do you need to be? Some jobs require more finesse than others.

- Frequency of Use: A jack for daily use should be more robust than one for occasional tasks.

- Portability Needs: Will you be moving the jack between locations, or will it have a permanent home?

- Budget: While it’s tempting to go for the cheapest option, remember that quality pays for itself in longevity and reliability.

The Cream of the Crop: Top Brands in Power Torque Jacks

While I can’t endorse specific brands, it’s worth noting that the market leaders in power torque jacks have earned their reputation through years of innovation and reliability. Look for brands with a strong presence in industrial and automotive sectors, and don’t be afraid to ask for recommendations from professionals in your field.

Power Torque Jacks in Action: Automotive Applications

For car enthusiasts and professional mechanics alike, power torque jacks are a game-changer. These versatile tools excel in tasks like precision engine positioning, transmission work, and even custom car modifications. Imagine being able to lift and rotate an engine block with pinpoint accuracy – that’s the power these jacks bring to your garage.

Manual vs. Power: The Great Jack Debate

While manual jacks have their place, power torque jacks offer several advantages:

- Effortless Operation: Say goodbye to back-breaking pumping and cranking.

- Higher Lifting Capacity: Power jacks can typically handle much heavier loads.

- Precision Control: The ability to make minute adjustments is unmatched in power models.

- Speed: Power jacks can complete lifting tasks much faster than manual alternatives.

However, manual jacks still win out in simplicity and portability for lighter tasks.

Keeping Your Jack in Top Shape: Maintenance Tips

To ensure your power torque jack remains a reliable workhorse, follow these maintenance tips:

- Regular Inspections: Check for wear, leaks, or damage before each use.

- Keep It Clean: Dirt and debris can wreak havoc on precision components.

- Proper Storage: Store your jack in a clean, dry place to prevent corrosion.

- Lubrication: Keep moving parts well-lubricated according to the manufacturer’s recommendations.

- Professional Servicing: Have your jack serviced by a professional annually or as recommended.

Safety First: Using Your Power Torque Jack Responsibly

With great power comes great responsibility. Always follow these safety guidelines:

- Read the Manual: Every jack is different, so familiarize yourself with your specific model.

- Use on Stable Surfaces: Ensure the jack and the load are on solid, level ground.

- Stay Within Limits: Never exceed the jack’s rated capacity.

- Use Jack Stands: For prolonged work under a lifted load, always use additional support.

- Wear Protective Gear: Safety glasses and steel-toed boots are a must.

- Keep Clear: Never place any part of your body under a raised load.

Precision Matters: Calibrating Your Power Torque Jack

To maintain accuracy, regular calibration is crucial. While professional calibration is recommended for critical applications, you can perform basic checks:

- Use a known weight to test lifting accuracy.

- Employ a torque wrench to verify rotational force precision.

- Consult your manual for model-specific calibration procedures.

Troubleshooting Common Issues

Even the best jacks can sometimes act up. Here are some common problems and quick fixes:

- Jack Won’t Lift: Check hydraulic fluid levels or electrical connections.

- Uneven Lifting: Look for air in the hydraulic system or uneven load distribution.

- Loss of Precision: Calibration may be needed, or there could be wear in the gears.

- Unusual Noises: This often indicates a need for lubrication or professional servicing.

Where to Find Your Perfect Power Torque Jack

While I can’t provide specific links, power torque jacks are available from a variety of sources:

- Industrial Equipment Suppliers

- Automotive Tool Retailers

- Online Marketplaces

- Specialty Hydraulic Equipment Dealers

Understanding the Investment: Power Torque Jack Pricing

Power torque jacks can range from a few hundred to several thousand dollars, depending on capacity and features. While it’s a significant investment, consider it in terms of increased productivity and safety. Many professionals find that a quality power torque jack pays for itself in time saved and reduced risk of injury.

Key Specifications to Consider

When evaluating power torque jacks, pay attention to:

- Maximum Lifting Capacity

- Minimum and Maximum Height Range

- Torque Output and Control Precision

- Power Source and Requirements

- Weight and Portability

- Warranty and After-Sales Support

Learning the Ropes: Resources for Mastering Your Jack

While I can’t provide direct links, there’s a wealth of information available online:

- Manufacturer Websites: Often offer detailed guides and video tutorials.

- YouTube Tutorials: Search for your specific model or general usage tips.

- Online Forums: Connect with other users to share tips and tricks.

- Local Workshops: Some suppliers offer hands-on training sessions.

Beyond Automotive: Industries Embracing Power Torque Jacks

These versatile tools have found homes in various industries:

- Aerospace: For precise positioning of aircraft components.

- Construction: Aligning heavy structural elements.

- Manufacturing: Assembling and maintaining large machinery.

- Shipbuilding: Positioning and aligning hull sections.

- Mining: Maintaining and repairing heavy equipment.

When Things Go Wrong: Advanced Troubleshooting

For more complex issues:

- Consult the troubleshooting section of your manual.

- Contact the manufacturer’s support line for guidance.

- Consider professional servicing for persistent problems.

- Keep detailed records of any issues for future reference.

Alternatives to Power Torque Jacks

While power torque jacks are versatile, sometimes alternatives might be more suitable:

- Chain Hoists: For vertical lifting without rotation.

- Hydraulic Presses: When downward force is needed.

- Crane Systems: For moving loads over larger areas.

- Manual Jacks: For simpler, lighter tasks.

Rent vs. Buy: Making the Smart Choice

For occasional users, renting can be a cost-effective option:

- Try before you buy to ensure it meets your needs.

- Ideal for one-off projects or infrequent use.

- Allows access to higher-end models without the full investment.

- Consider long-term rental vs. purchase costs for regular use.

In conclusion, power torque jacks represent a significant leap forward in lifting and positioning technology. By understanding their capabilities, maintenance needs, and proper usage, you can harness their power to transform your work processes. Whether you’re a professional tackling industrial-scale projects or a dedicated DIYer pushing the boundaries of your home workshop, a power torque jack could be the game-changing tool you’ve been searching for. So go ahead, lift smarter, not harder!